How Does A Sand Blasting Machine Work?

Sand Blasting Machine

What Is A Sand Blasting Machine?

Sand blasting machine uses pressurized air from an

air compressor to blast materials through a nozzle, such as aluminum oxide,

glass beads, etc. There are three types of sandblasting machines: blower,

direct pressure, and gravity suction. Using suction force to recirculate the

blast media inside the dust collector, the media are cleaned of foreign objects

and blasted again. The dry approach is less harmful to the environment.

In essence, using an air

compressor to blast away rust, grime, and other deposits from metal surfaces is

the most affordable and effective method of surface preparation. Sandblasting

machines run on compressed air, which propels the abrasive materials to strike

the surface at high speeds to remove deposits and impurities such as dirt and

rust.

More pressure from a sandblaster

would result in a more intense rate of blast media hitting the metal surface,

which would improve cleaning; nevertheless, overly harsh sandblasting will

damage several materials. Because of this, it is crucial to consult a sandblast

machine manufacturer who can advise on the necessary compressed air and

pressure levels.

How Does A Sandblasting Machine Work (Components)

The blast pot serves as a media

reservoir and sustains the blasting pressure. The nozzle type chosen determines

the pace at which media can be sprayed. Inlet and outlet valves check if the

pot is pressurized by monitoring the airflow into and out of the container.

When pressure is applied to the system, the pop-up valve pops up and

pressurizes the system.

The sandblasting media valve

controls the blast pot's abrasive flow. Abrasive media valves contain one

outlet and two recesses; the outlet is for the mixture of air and abrasive that

will be transported through the blast hose. The inlet is for abrasive, and the

opposite is for air. Abrasive cannot pass through the exit valve because of the

abrasive lure.

The management handles one hose

and monitors air flowing towards the nozzle, while the other hose regulates air

flowing back towards the recessed valve. The twin-line hoses are attached to

each recess valve. There will not be any blasting when the management handle is

disengaged because there is free air at the bottom of the handle. Through the

nozzle, an abrasive and air mixture can be sprayed.

Following the media's loading

into the device, several things should happen for it to begin blasting.

Pressure is essential to the success of this entire process; without it,

nothing would happen, and your fender would get rusty.

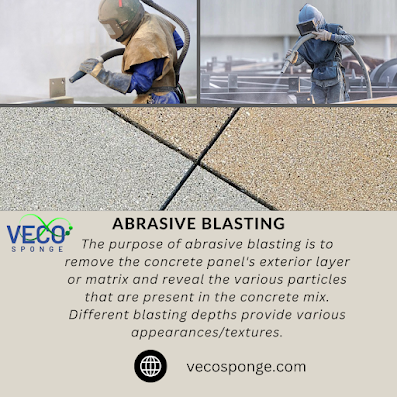

Applications of Sandblasting

Sandblasting is

one of the most affordable ways to clean and prepare surfaces. Sand blasting machine is utilized by woodworkers, machinists, automobile vehicle technicians,

and other businesses in their job, especially once they have a thorough

understanding of the diverse applications of sandblasting.

Contrary to its

name, sand is not the only ingredient used in sandblasting. Different abrasives

are frequently utilized depending on the type of material they are being used

on. These abrasives include glass beads, walnut shells, aluminum oxide, and

more. Removing paint or rust is one of the most significant applications of

sandblasting. Sandblasters are frequently used to remove paint, rust, and other

surface impurities from vehicles, homes, equipment, and other surfaces.

It is not

necessary to limit the use of sandblasting to large machinery or structures.

Even clean ménage tools can be used with it. A brief blast with the sandblaster

cleans rusted or unclean screwdrivers, wrenches, and other metal tools quickly

and efficiently. Occasionally, small burs or other abnormalities in metal or

plastic components of devices that need to be built change their intended form or

enter the assembly space during the process. Sandblasting is the process used

to remove such tags, burs, and extra material.

Sandblasting can

also effectively clean streets, walkways, and other concrete surfaces. Without

water, the high-speed abrasives shot from a hand tool will thoroughly clean concrete

and pavement rapidly.

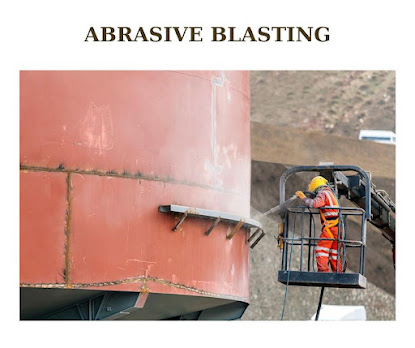

Industrial Uses of Sandblasting

Metal surfaces and components must be cleaned, rusted out, descaled, and debarred for various industries. Sand blasting machine is used for surface preparation because manual sanding is a wasteful method that makes cleaning metal surfaces nearly impossible.

After employing a sandblasting machine, metal surfaces are cleaned in minutes since sandblasting involves using compressed air to force solid abrasive particles across a hard metal surface at high speeds. Industries employ two primary types of sandblasting machines: portable sandblasters and sandblast cabinets.

Sandblasting equipment can effectively remove paint, corrosion, and oxidation residue from various metal surfaces. The sandblasting method can also be used to modify the surface condition of a metal by eliminating burrs and scaling from forging, casting markings, and scratches. For centuries, the sandblasting process has been used in various sectors as a cleaning and surface preparation technique.

What Are The Benefits of A Sand Blasting Machine?

The

following are some of the benefits of a sand blasting machine:

Easy process

Sandblasting is a straightforward and effective process. Even tiny

sandblasting equipment can quickly clean and prepare metal surfaces than

manually sanding with sandpaper.

Less Machinery

The sandblasting

method requires a nozzle, a blasting pot, and a mechanical device. To blast,

you must aim the nozzle close to the surface, apply an appropriate abrasive,

and adjust the compressed air pressure.

Wide Applications

Sandblasting has

several uses in various industries, including automotive, aviation,

construction, food processing, and industrial manufacturing. Sandblasting

machines are an extremely effective and cost-effective way to remove dust,

rust, and other contaminants from metal surfaces, eliminating the agony

associated with these tasks.

Enhanced Efficiency

By reducing the

time needed to clean components, sandblasting increases production efficiency

and enables manufacturers to raise the caliber of their output.

Repainting

In addition to

enhancing metal surfaces, paint removal is another common application for

sandblasting. Sandblasting is the most effective method if repainting a metal

building requires removing existing paint from the surface.

Conclusion

By using the

abrasive qualities of sand, sandblasting produces smoother surfaces with fewer

visible faults and imperfections. It goes without saying that sand is abrasive

and grainy. These characteristics enable it to remove extraneous or surplus

material from a surface.

The work piece

surface is thoroughly cleaned due to the abrasive sand's hitting and cutting

action. The mechanical performance and surface quality are also significantly

enhanced at the same time. As such, it finds widespread application across

numerous industries and for a wide range of functions.

Comments

Post a Comment