Can I Use Abrasive/ Sandblasting Technique on Concrete Surfaces?

The quick answer is YES!

Abrasive blasting, formerly known only as "sandblasting," is a typical optional procedure used on precast concrete panels to produce an attractive appearance.

Concrete naturally cures in a variety of gray tones. Concrete's color can be changed by adding powders or dyes. The color and texture of exposed concrete can also be altered by the sandblasting procedure.

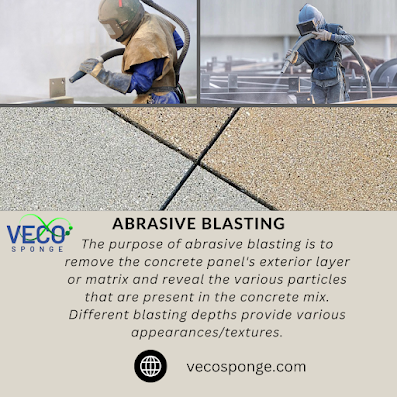

The purpose of abrasive blasting is to remove the concrete panel's exterior layer or matrix and reveal the various particles that are present in the concrete mix. Different blasting depths provide various appearances/textures.

Choosing The Right Abrasive Matters a Lot When It Comes to Sandblasting

Choose an abrasive that is appropriate for the surface you are working on and the outcome you desire. Use the finest abrasive possible to get the greatest results.

The ideal materials are silica sand or glass beads for cleaning paint, grease, and dirt off of concrete. Denser or harsher abrasives can produce a deeper cut. The shape should also be taken into consideration. More rounded particles cut less deeply than angular media.

The concrete's aggregates become more important to the final appearance with each level of blasting.

|

| Abrasive Blasting |

Why Go for Concrete Sandblasting?

Concrete sandblasting offers several advantages over conventional surface repair techniques:

· Compared to employing conventional methods, it ensures uniform concrete finishes in the uniformity of the cement and stone ratio.

· Sandblasting is a far less expensive and time-consuming alternative to removing the existing concrete, throwing away the scrap, and then laying a fresh layer of concrete.

· Its approach avoids irreversible surface damage by using compressed air to project abrasive material at the concrete for an exposed aggregate.

· Concrete can be efficiently and affordably restored to its original surface condition with Sandblasting, requiring little work in the setup for subsequent treatment.

Abrasive Blasting on Concrete: How It Works?

1. Some precautions should be taken in and around the sandblasting area in order to prevent damage caused by the operation. In order to preserve them and maintain their cleanliness, for instance, remove any materials that can be moved, cover any items that cannot be moved, and cover any open surfaces near the operation area, including windows.

2. Adequate ventilation must be provided if sandblasting is done in a closed space, such as a garage.

3. To avoid inhaling dust during sandblasting operations, workers must wear safety goggles, suits with hoods, and respirators.

4. Stencils must be fixed before the sandblasting process can start since they are installed to achieve a specific texture.

5. Close all the valves on the sandblaster equipment, and then fill the tank with sand or other suitable sandblasting ingredients like soda, silica or silicon dioxide, steel grit, glass beads, or bristles.

6. Start the compressor, and lower the pressure to somewhere between 275 MPa and 0.689 MPa.

7. Point the nozzle at the concrete while maintaining a 20- to 40-cm gap between it and the operator's body.

8. Next, begin abrasive blasting the concrete surface from top to bottom to ensure even coverage. When cleaning concrete and achieving the desired texture, the nozzle must be kept 30.5 cm away from the surface. A skilled operator can choose the nozzle location to create the desired surface finish rapidly.

9. Use brief bursts of sand in areas that are challenging and sweeping motions on other areas of the concrete.

10. After performing the task, blow some compressed air over the surface. Fill a wheelbarrow with all the used sand before hauling it away.

What About the Time?

Economics will determine when the blasting should be done. In the first 24 to 72 hours following casting, it will be simpler to cut the concrete matrix. The operator should hold the nozzle perpendicular to the surface and around 2 feet away when blasting a surface.

The precise distance is determined by the pressure applied, the degree of concrete matrix hardness, and the abrasive's capacity for cutting. A skilled operator can choose the nozzle location to create the desired surface finish rapidly.

Using Proper Abrasive Blasting Technique is Vital

Start by blasting a small, inconspicuous area to test the results before blasting the entire surface. In the event of disappointing outcomes, this will save you from damaging a sizable surface.

For

the abrasive blasting to be effective against the concrete, the walking

speed must be constant but not excessive. Point the nozzle at the surface while

positioning it 8 to 16 inches away from your body. Maintain the same distance

from the surface throughout the operation to guarantee uniform penetration.

Adjust the pressure setting as necessary after a few passes. Use short spurts to maintain uniformity around bends and confined areas.

Can Sandblasting Removes Paint from Concrete Surfaces?

The majority of surfaces are difficult to remove paint from, as many of us have learned, especially those that are extensively coated or were painted in the past. Chemical stripping chemicals have a lot of limitations, and there's always a danger they won't complete the task.

When repainting a surface that hasn't been completely stripped, it can be challenging to achieve flawless results; but, when we sandblast the paint off your concrete, there are no such concerns.

Concrete paint can be safely and successfully removed using sandblasting. It takes a lot less time and requires less work than other approaches. With manual sanding methods, it is nearly difficult to reach the smallest cracks, but our sandblasting equipment can.

Wrap Up

Veco Sponge is one of Singapore’s top companies for sandblasting exposed aggregate concrete, which is a great way to repair damaged or worn-out concrete and lay fresh concrete.

For concrete, there are numerous sandblasting methods available. These consist of:

• Open-air aggregate

• Regularity

• Applications that prevent slipping

• Removal of unwanted coatings including paint, grime, grease, or unfavorable chemicals

In addition to their focus in sandblasting, Veco Sponge provides garnet blasting services to both commercial and residential clients in the region.

They are committed to providing our clients with the best sandblasting and Sponge blasting media and they will collaborate with you to get excellent outcomes. Call them right now to request more details.

Comments

Post a Comment