How Does A Sand Blasting Machine Work?

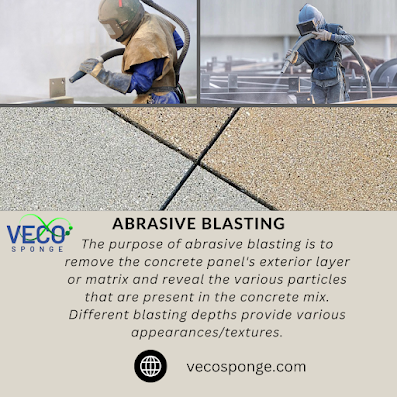

Sand Blasting Machine What Is A Sand Blasting Machine? Sand blasting machine uses pressurized air from an air compressor to blast materials through a nozzle, such as aluminum oxide, glass beads, etc. There are three types of sandblasting machines: blower, direct pressure, and gravity suction. Using suction force to recirculate the blast media inside the dust collector, the media are cleaned of foreign objects and blasted again. The dry approach is less harmful to the environment. In essence, using an air compressor to blast away rust, grime, and other deposits from metal surfaces is the most affordable and effective method of surface preparation. Sandblasting machines run on compressed air, which propels the abrasive materials to strike the surface at high speeds to remove deposits and impurities such as dirt and rust. More pressure from a sandblaster would result in a more intense rate of blast media hitting the metal surface, which would improve cleaning; ...